Which molecular sieve can produce oxygen?

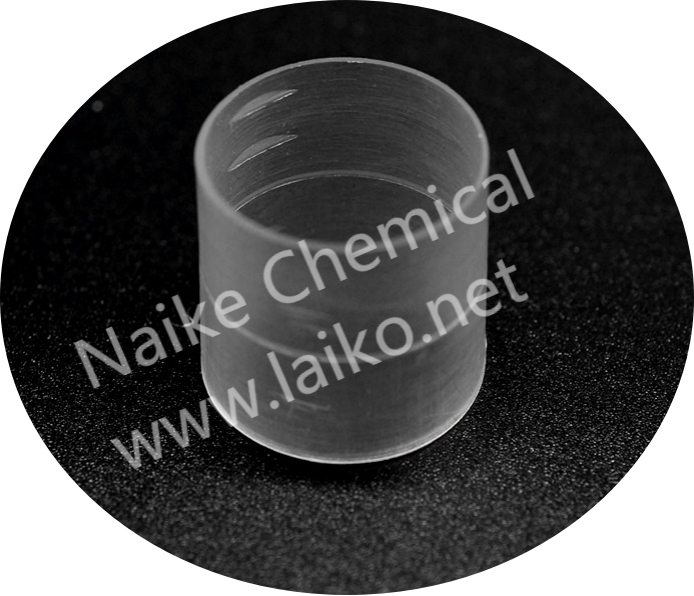

Which molecular sieve can produce oxygen? Zeolite 13x hp and Lithium Zeolite Unveiled as Pioneering Forces in Oxygen Production Technology. In a major stride forward for oxygen generation, researchers have unveiled the remarkable capabilities of 13x hp and Lithium Zeolite. These two molecular sieves are poised to redefine the landscape of oxygen production, offering enhanced efficiency and novel applications in various industries. 13x hp molecular sieve Scientists have identified 13x hp molecular sieve as a key player in the realm of oxygen production. Renowned for its high-performance characteristics, 13x hp exhibits an exceptional ability to selectively adsorb nitrogen, making it…