Overview of Raschig Rings

What are raschig rings?

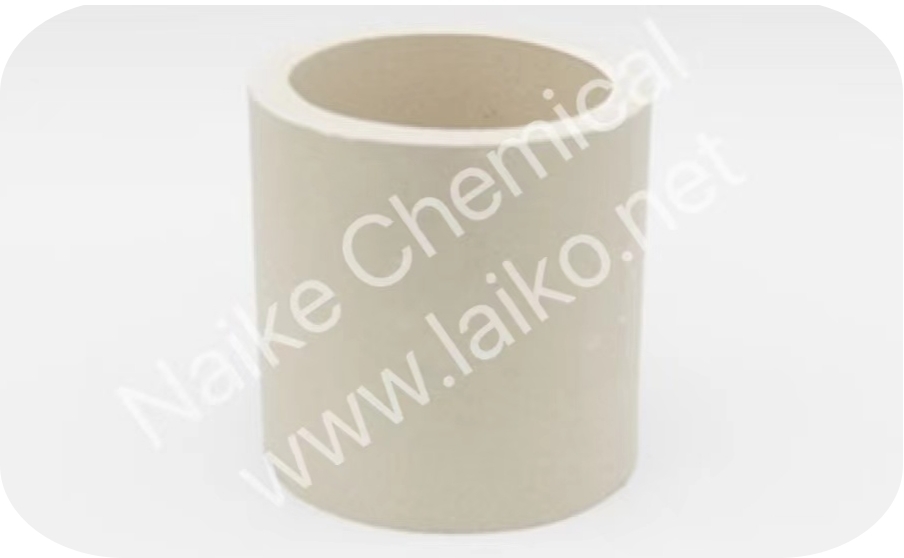

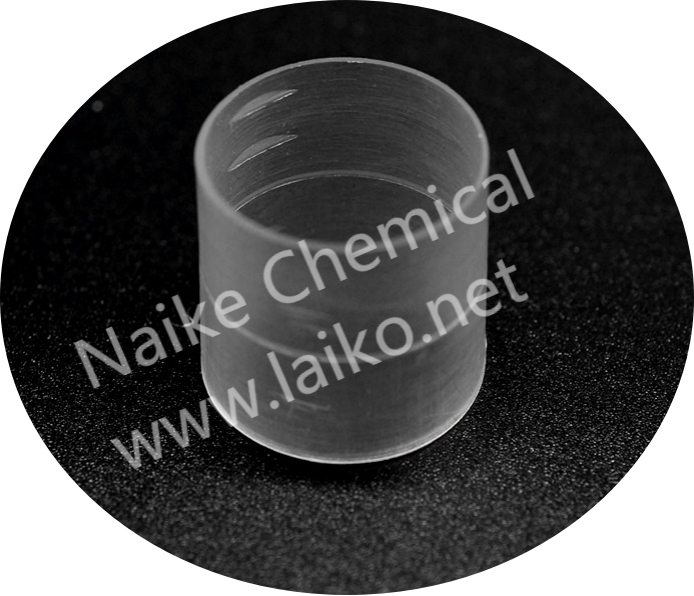

Rasching ring is one of the first artificial fillers used in the industry. Usually made of ceramic or metal sheet, its height is equal to the diameter, and the common size is 25mm~75mm (there are also as small as 6mm and as large as 150mm). The wall thickness of ceramic is 2.5mm~9.5mm, the metal ring is 0.8mm~1.6mm, and the wall of a ring should be thinned as much as possible under the condition of strength permitting. Rasching ring is not ideal for mass transfer performance, but it is still used by some factories due to its simple structure, easy manufacturing, and low price. Rasching ring materials include plastic rasching rings, metal rasching rings, and ceramic rasching rings. Rasching ring has excellent acid and heat resistance and can resist corrosion of various inorganic acids, organic acids, and organic solvents except for hydrofluoric acid, which can be used in various high and low occasions and has a wide range of applications.

What do raschig rings do?

Rasching rings form random packing and allow Raschig to perform distillation with much higher efficiency than their competitors using fractionation columns with trays. In a distillation column, refluxed or condensed vapor flows down the column and covers the surface of the ring, while vapor from the reboiler flows up the column. As the vapor and liquid flow upwards against each other in a small space, they tend to equilibrate. As a result, the less volatile substances tend to go downward, while the more volatile substances go upward.

are also used in equipment where gases and liquids are in contact for absorption, stripping, or chemical reactions, and as supports for biofilms in bioreactors.

made of borosilicate glass is sometimes used for handling nuclear materials. They are used inside vessels and tanks containing solutions of fissile materials, such as enriched uranium nitrate solutions, where acts as neutron absorbers to prevent criticality accidents.

How to clean raschig rings?

Raschig rings cleaning before the following supplies need to be prepared: safety cap, safety glasses, acid-proof gloves, protective clothing, acid-proof shoes, plastic leak basin, stainless steel shovel, sink, high-pressure water gun, plastic textile bags, and rope.

After the supplies are ready, first check the filler layer, and see the filler surface condition; if the surface has a large piece of adhesion should be stopped to replace the processing, washing tower cast unloading port operation: prepare several large bags to fill the material in advance, dismantle the unloading port blind, will rasching rings pulled out in the bag; hollowed out after sealing the blind, dismantle the upper feeding port, isolate the entrance into the acid pipe, from the upper feeding port with Clean the inside of the tower with tap water from the upper feeding port.

Replace need to stop all equipment operation, first open the window to the internal filling layer of rasching rings filler hollow out, placed in a large container, with a high-pressure water gun to clean the surface of the adhering dirt; single cleaning the amount of not too much otherwise it will not clean. The cleaned rasching rings can be stored as spare parts by natural air-drying or sun-drying and can be placed indoors.