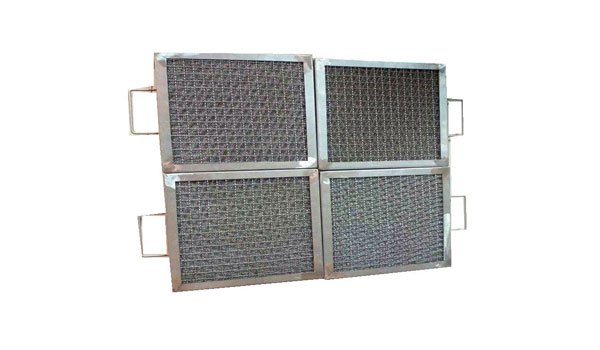

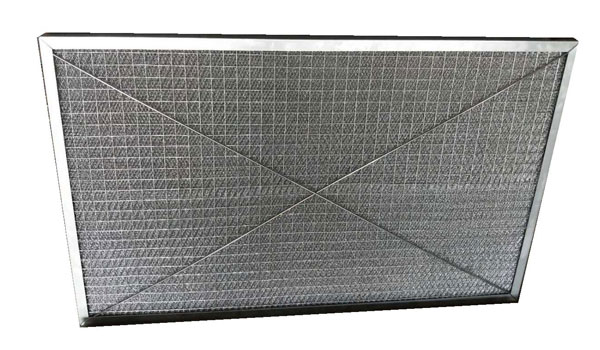

Pad Demister With Frame/Mist Eliminator With Frame

Pad Demister With Frame/Mist Eliminator With Frame

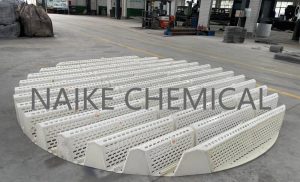

Knitted Wire Mesh is a kind of wire mesh knitted in particular type. It is used for wire mesh demister, oil-gas separator, dust remover, dedusting apparatus, environmental protection device, various separating and filtering devices, filtering eliminate for auto and tractor, sealing, shock absorption, muffling and purifying components for auto, as well as used for electromagnetic interference and shielding devices for electric apparatus.

描述

Parameters of Pad Demister

With Frame/Mist Eliminator With Frame

| Model | 40-100 60-150 ,140-400 | ||

| Weight capacity | 168 Kg/m3 | ||

| Specific surface area | 529.6 m2/m3 | ||

| Porosity | 0.9788ε | ||

| High efficient type | |||

| Model | 60-100 80-150 200-400 80-100 | ||

| Weight capacity | 128 Kg/m3 | ||

| Specific surface area | 403.5 m2/m3 | ||

| Porosity | 0.9839ε | ||

| High Running type | |||

| Model | 20-40, 30-80, 40-120,50-120 | ||

| Form code | HR | ||

| Weight capacity | 168 Kg/m3 | ||

| Specific surface area | 529.6m2/m3 | ||

| Porosity | 0.9788ε | ||

Demister Pad Material

Demister pads are commonly used in industrial processes to remove liquid droplets from gas streams. They consist of a mesh of knitted or woven metal wires or synthetic fibres that provide a large surface area for droplets to coalesce and form larger droplets that can be removed from the gas stream.

The most commonly used materials for demister pads are stainless steel and polypropylene. Stainless steel is a durable and corrosion-resistant material that can withstand high temperatures and harsh chemical environments, making it suitable for use in a wide range of applications. Polypropylene, on the other hand, is a lightweight and cost-effective material that is often used in less demanding applications.

Other materials that can be used for demister pads include copper, aluminium, and various types of synthetic fibres, such as polyester and nylon. The choice of material depends on the specific requirements of the application, such as the gas flow rate, temperature, and chemical composition.

Demister Pad Installation

Installing a demister pad requires careful consideration of several factors, such as the type of equipment it will be used in, the gas flow rate, and the desired level of efficiency. Here are some general steps to follow when installing a demister pad:

Determine the appropriate size and shape of the demister pad based on the equipment and process requirements.

Install the demister pad in the designated location, making sure it is properly secured and supported to prevent movement or damage.

Ensure that the gas flow direction is perpendicular to the face of the demister pad to maximize its efficiency.

Provide adequate clearance around the demister pad to allow for proper gas flow and prevent any interference with adjacent equipment or structures.

Check the demister pad regularly for signs of wear or damage, and replace it if necessary to maintain optimal performance.