What is metal pall ring?

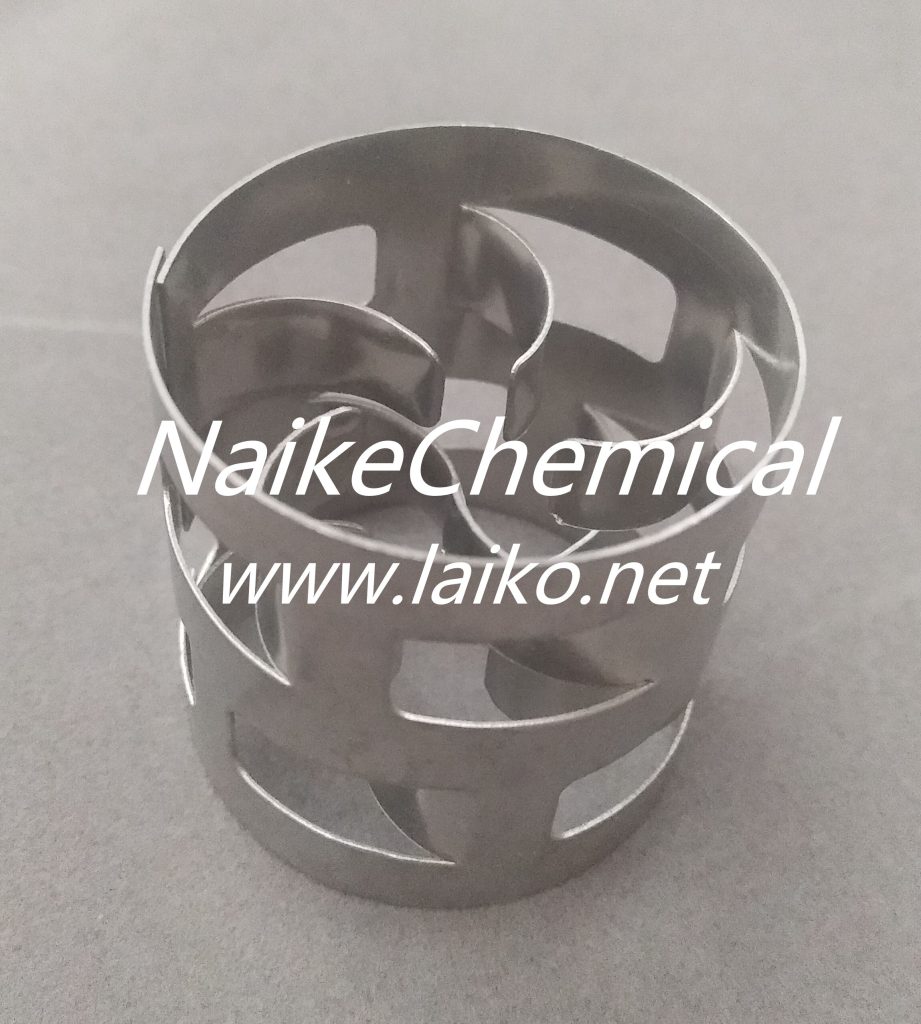

1. Open Structure: The pall ring has a unique geometric structure with windows or openings on the surface. This open design allows for increased liquid and gas contact points, enhancing mass transfer.

2. Multi-Faceted Surface:The exterior of the metal pall ring is often characterized by multiple internal and external surfaces, creating a complex network of contact points. This design promotes turbulent flow and helps prevent the packing from nesting or stacking, which can occur with simpler shapes.

3. High Surface Area: The pall ring’s shape and surface features provide a large specific surface area, facilitating efficient mass transfer and promoting separation processes.

4. Improved Liquid Distribution: The open structure and internal features of the pall ring contribute to better liquid distribution over the packing surface, ensuring uniform contact with the gas phase.

5. Resistance to Fouling: The design minimizes the likelihood of fouling, which occurs when deposits accumulate on the packing surface and impede the flow of fluids. This is particularly important for maintaining the efficiency of industrial processes over time.

Metal pall rings are commonly made from materials such as stainless steel, aluminum, or other corrosion-resistant alloys, depending on the specific requirements of the application. They find widespread use in chemical processing industries, including petrochemical, pharmaceutical, and environmental applications, where efficient separation and reaction processes are essential.