The Difference Between MBBR And MBR

What is MBBR filter media?

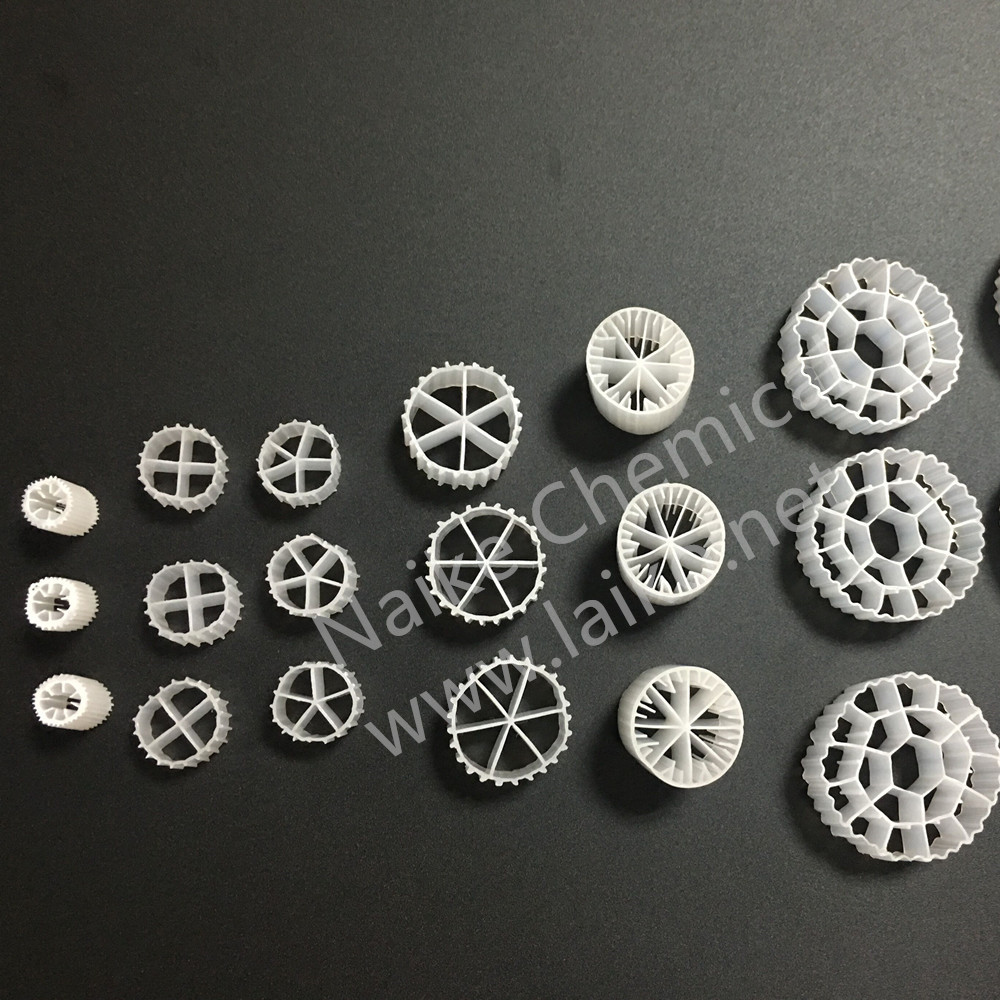

What is MBBR media? MBBR media is also known as MBBR biological media and MBBR carrier. MBBR means moving bed biofilm reactor, which is a microbial carrier used in the MBBR process. It is used mainly to provide a suitable growth environment for microorganisms.

The MBBR packing adopts a scientific formula. According to the different properties of the sewage, a variety of trace elements s are integrated into the polymer material that can conducive to the rapid attachment and growth of microorganisms. It is modified and constructed by a special process, which has a large specific surface area, good hydrophilicity, and biological properties. It also has the advantages of high activity, fast film hanging, good treatment effect, and long service life.

How is MBBR used in Wastewater Treatment?

MBBR is a biological process, not a chemical or mechanical process, which is a suitable and economical solution for wastewater treatment processes for municipal and industrial applications. It is used for the separation of organics, nitrification, and denitrification. The MBBR design consists of an activated sludge aeration system. The sludge is collected on a plastic carrier with a large internal surface area. The surface area of the carrier optimizes the contact of water, air, and bacteria.

The principle of the MBBR process is to use the basic principle of the biofilm method. By adding a certain amount of suspended carrier to the reactor, increasing the biomass and biological species in the reactor are increased to improve the processing efficiency of the reactor. Since the density of the MBBR packing is close to that of water, it is in a state of complete mixing with water during aeration. The collision and shearing of the carrier in the water make the air bubbles smaller and increases the utilization rate of oxygen. In addition, each carrier has different biological species inside and outside. Some anaerobic bacteria or facultative bacteria grow inside, and aerobic bacteria grow outside. Each carrier is a microreactor, so nitrification reaction and denitrification reaction can exist at the same time to improve the processing effect.

What is the difference between MBBR and MBR?

Different definitions: MBR means membrane bioreactor while MBBR is moving bed biofilm reactor.

Different working principle: MBR is activated sludge method + membrane separation. MBR (Membrane Bioreactor) is a new type of water treatment technology that combines a membrane separation unit with a biological treatment unit. It replaces the secondary sedimentation tank (or decanter) with a membrane module and maintains highly activated sludge in the bioreactor. Maintaining a high activated sludge concentration reduces the footprint of the wastewater treatment facility and reduces sludge volume by maintaining a low sludge load.

In terms of removal of organics: both processes have higher removal rates for COD, BOD, and ammonia nitrogen. The MBR process relies on its higher sludge load, and the MBBR process relies on the biofilm in its packing.

Comparison of TN and TP removal rates: The MBBR process has a better effect on TN removal, while the TP removal relies on dosing chemical phosphorus removal. MBR film has no removal effect on TN, it relies on front-end biological removal. And The removal of TP also relies on front-end dosing chemical phosphorus removal.

SS removal comparison: MBBR has no effect on SS removal, and needs to rely on the back-end ultrafiltration membrane process to remove SS; MBR membrane can remove SS better.

Comparison of cost treatment: The packing in the MBBR process is added only once. In the subsequent operation, it only needs to strengthen the biofilm management on the packing. The investment in the construction period is relatively large, but the operation and maintenance are simple. The replacement cycle of the MBR process is short, and the service life of the MBR process membrane unit is generally 4-5 years. During daily operation and management, it is necessary to carry out maintenance work such as chemical cleaning and off-line cleaning of the membrane unit, which is difficult to manage and costs highly.

Naike Chemical is one of the leading MBBR bio-filter media manufacturers and suppliers in China. You can get the best price from us.