Random Packing VS. Structured Packing

Packing generally refers to materials that are filled with other objects. In chemical engineering, packing refers to the inert solid materials installed in the filling tower, such as Pall ring and Lacey ring, whose role is to increase the contact surface between the atmosphere and liquid, so that they mix strongly with each other. The purpose of packing is to create surface area for vapor/liquid contact so that Mother Nature (and Father Thermodynamics) can produce chemical separation. Chemical separation includes distillation, absorption, and stripping. There are two main types of packing used in mass and heat transfer applications: random packing and structured packing. The article will tell the differences between random packing and structured packing.

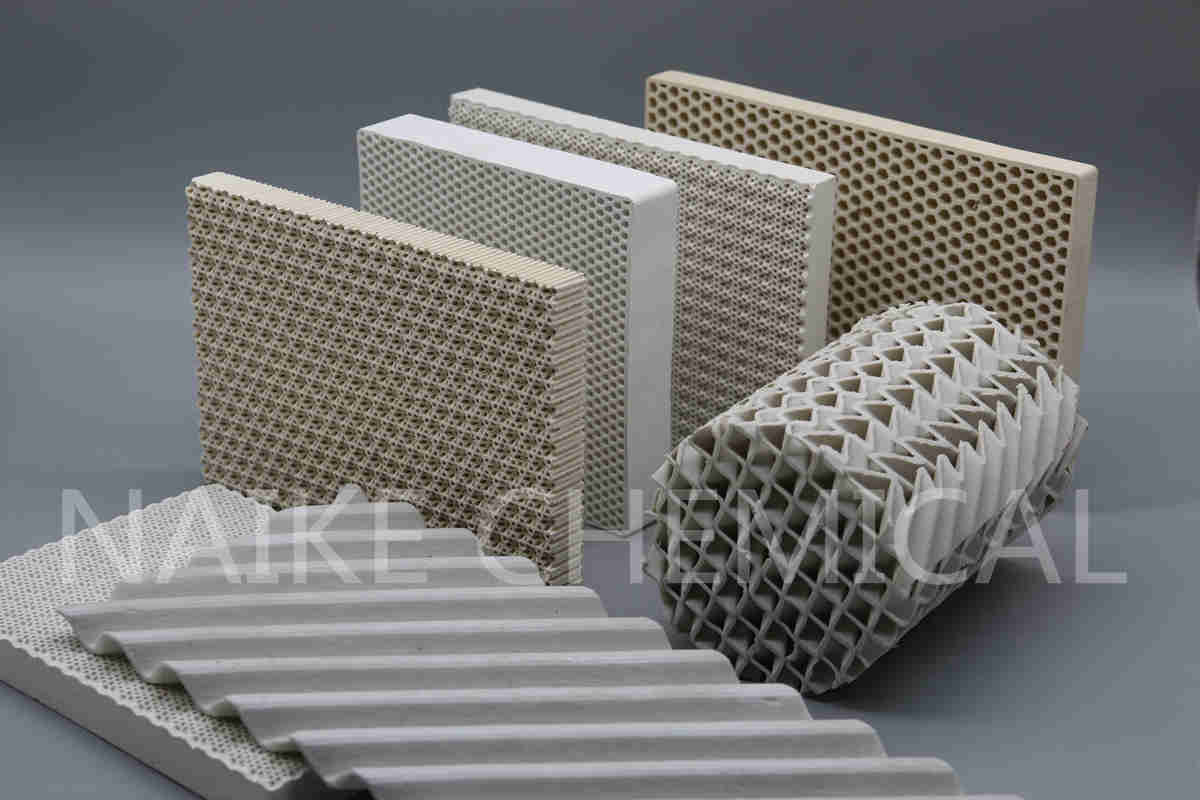

What is structured column packing types?

Structured tower packing is a kind of packing arranged in a uniform geometric pattern. The packing material is stacked neatly in the structured packing distillation column composed of a number of packing units having the same geometry. is used in packed tower distillation. There are various structured packing types provided by professional Laiko, such as Ceramic Structured Packing, Metal Structured Packing, Plastic Structured Packing.

What is random tower packing types?

Random tower packing is a kind of packing stack the packing material in a random pattern. The packing material is a particle body with a certain geometric shape and size, generally stacked in a random packing column. There are various types, such as Pall Ring, Wire Gauze Packing, Intalox Saddle. Random packing is used in the distillation column to increase the vapor/liquid contact so that the chemical separation is more efficient.

What is the difference between structured packing and random packing?

Random vs Structured packing

1. Compared with random packing, structured packing has higher processing efficiency and lower cost for the same theoretical plate number and handling capacity, but random packing is more anti-blocking than structured packing. So in practical application, they tend to use random packing at the bottom tower section, while using the regular packing at the top section.

2. Random packing has the advantages of large specific surface area, small pressure drop, uniform fluid distribution, high mass, and high heat transfer efficiency, while random packing has the advantages of improved contact area, mass transfer, and higher cost-effectiveness.

3. The structured packing has higher flexibility of operation compared with random packing. The processing capacity of structured packing is larger and the gas-liquid distribution is more uniform.

4. Random packing is easy to maintain, and generally dirty materials are used in random packing