How does Pall Ring Work?

In a breakthrough for chemical processing, the application of Pall Rings has surged as industries embrace the innovative design’s efficient mass transfer principles. The Pall Ring’s distinctive structure is proving instrumental in enhancing separation and purification processes across various industrial applications.

Revolutionary Design:

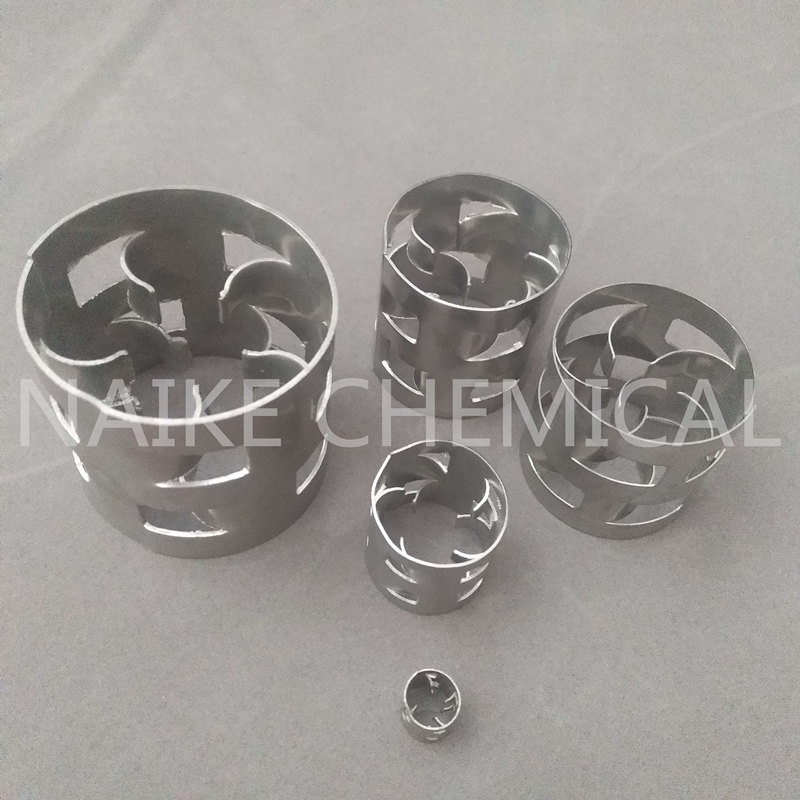

The Pall Ring’s success lies in its unique design, featuring a series of windows and internal structural elements. This design optimizes surface area and facilitates superior gas-liquid distribution, setting it apart from traditional packing materials. The revolutionary structure maximizes efficiency in mass transfer, making it a sought-after solution for industries seeking advanced performance.

Principles of Mass Transfer:

The application principle of Pall Rings centers around the fundamental principles of mass transfer. As fluids move through packed beds of Pall Rings, the increased surface area and optimized distribution of the rings promote efficient contact between the gas and liquid phases. This, in turn, enhances the mass transfer process, allowing for improved absorption, stripping, and distillation.

Versatility in Industrial Processes:

Pall Rings find application across a spectrum of industries, including chemical, petrochemical, and environmental sectors. Their versatility is evident in various processes, such as gas absorption towers, distillation columns, and stripping applications. The unique design enables Pall Rings to adapt to diverse chemical processing scenarios, providing a flexible and efficient solution.

Enhanced Efficiency and Performance:

Industries adopting Pall Rings report significant improvements in efficiency and overall performance. The increased surface area and optimized gas-liquid contact result in enhanced mass transfer rates, reducing pressure drop and improving separation processes. The application of Pall Rings translates into more productive and cost-effective industrial operations.

Sustainability and Environmental Benefits:

The efficient mass transfer principles of Pall Rings contribute to sustainability in chemical processing. By reducing energy consumption and optimizing performance, Pall Rings align with the industry’s growing emphasis on eco-friendly practices. This eco-conscious approach makes Pall Rings an attractive choice for companies committed to reducing their environmental footprint.

Future Developments and Research:

The success of Pall Ring applications has spurred ongoing research and development initiatives. Scientists and engineers are actively exploring ways to further refine the design and materials used in Pall Rings, aiming to unlock additional applications and optimize their performance for specific industrial processes.

The surge in Pall Ring applications highlights the industry’s recognition of the innovative design’s efficient mass transfer principles. As industries continue to prioritize enhanced performance, flexibility, and sustainability, Pall Rings are set to play a pivotal role in shaping the future of chemical processing. The principles governing Pall Ring applications promise a more efficient and environmentally conscious era in industrial operations.